Improving Visibility into Efficiency Losses & On-Time Delivery Delays

Customers often ask us how to improve visibility into productivity-related efficiency losses and delays that impact on-time delivery.

The key, as we often recommend, is to establish the right infrastructure for recording these delays and to ensure they are reviewed regularly—at least once per month.

At Smart-QC, we address this challenge by providing key tracking capabilities, including:

✅ Efficiency delays in QC labs – Tracking touch time/hands-on time losses.

✅ Execution delays – Monitoring late starts, unexpected delays during testing, and late completions (depending on LIMS integration).

By recording and analyzing these delays, we gain valuable insights to improve both efficiency and on-time execution:

🔹 Efficiency Optimization:

✅ Identifying delays caused by equipment failures (potentially linked to maintenance gaps or lack of predictive maintenance programs).

✅ Recognizing recurring method failures—critical feedback for analytical development teams.

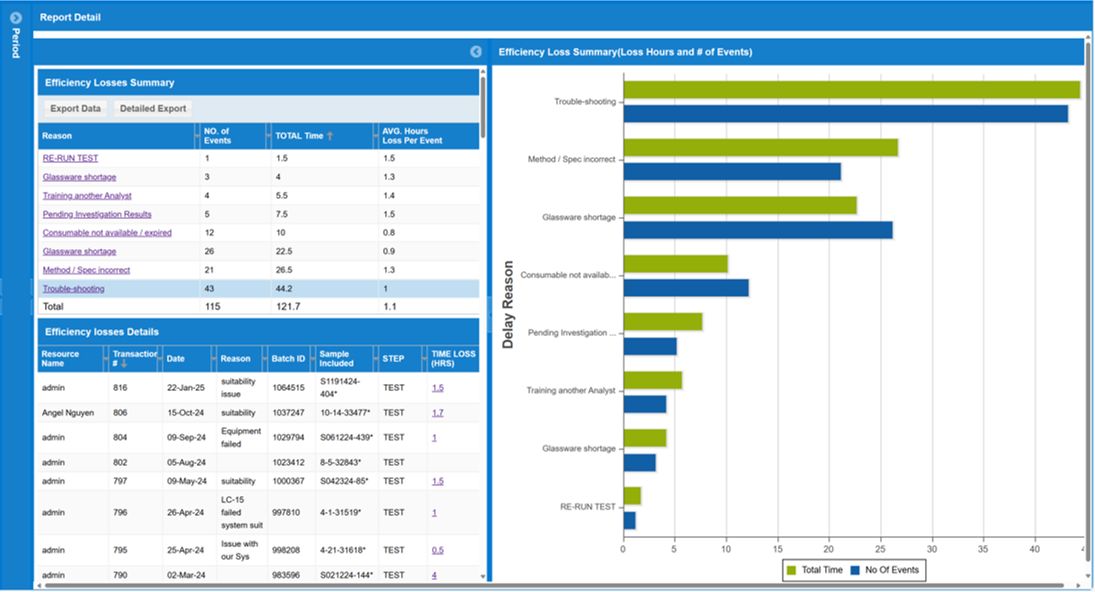

✅ Smart-QC captures event frequencies, quantifies time losses, and provides Pareto analysis to focus on root causes.

🔹 On-Time Execution Improvement:

✅Addressing delays caused by missing reagents, pending investigations, or other bottlenecks.

✅ Providing clear visualizations to pinpoint key delay reasons that impact team performance.

With Smart-QC, teams can move from reactive problem-solving to proactive efficiency improvements, ensuring smoother operations and better on-time performance.

How does your organization track and address efficiency and execution delays? Let’s discuss in the comments!