The Conflict Between On-Time Delivery and Cycle Time

We sometimes seeing organizations shifting their focus away from reducing cycle time, and instead concentrating primarily on improving on-time delivery.

Reducing cycle time delivers multiple operational and strategic benefits:

✅ Lower inventory: Shorter cycles reduce WIP and finished goods inventory.

✅ Faster response to issues: Production deviations, equipment problems, or quality issues surface sooner and can be corrected quickly and expose fewer batches to the issue identified at the lab.

✅ Shorter lead times: Customers receive products faster, improving agility and competitiveness and more …

🔍 Cycle time is a key indicator of the health of an organization

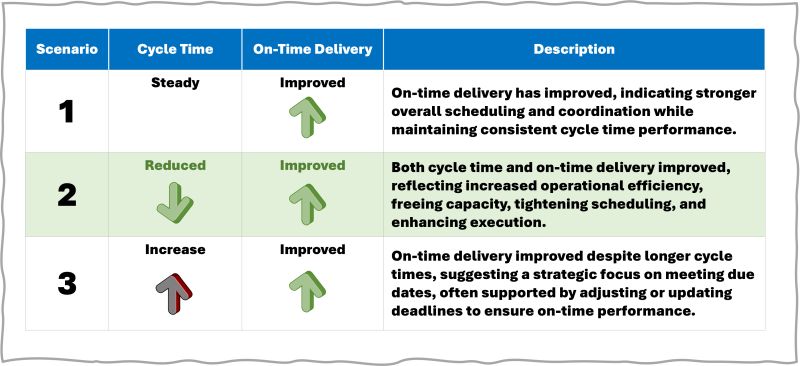

So what is the paradigm issue with on-time delivery? The key challenge is that you cannot sustainably improve on-time delivery without addressing cycle time, efficiency, capacity constraints, and other operational factors.

What we often see in organizations is that labs meet with supply chain and mutually agree to push out due dates for seemingly valid reasons.

This enables the lab to maintain a high on-time delivery rate because the target becomes a moving one. If a deadline is about to be missed, it simply gets updated allowing the team to “meet” the postponed due date.

This is exactly why organizations cannot rely solely on on-time delivery as a performance measure.

⚡Cycle time,

⚡efficiency,

and other supporting KPIs must also be carefully monitored to prevent this syndrome and to drive true operational improvement.