Customers often ask us about the best approach to managing On-Time Delivery (OTD) using Smart-QC.

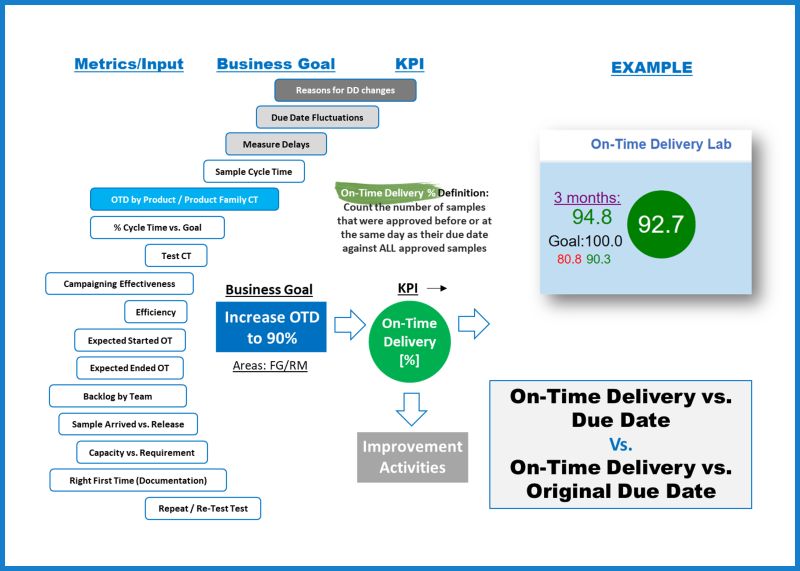

In a previous post, we discussed the relationship between Cycle Time (CT) and OTD. This time, we’ll focus on an approach to managing and improving OTD.

Cycle Time and On-Time Delivery are key indicators of lab operational health. Prolonged cycle times lead to high inventory levels and slow feedback to manufacturing (MFG), which can put multiple batches at risk.

On the other hand, fluctuating delivery performance also affects inventory and customer service, often due to poor on-time delivery.

By now, it is clear that both CT and OTD must be addressed together as part of a continuous service-level improvement journey—one cannot be optimized without the other.

In labs facing significant backlog, capacity shortages, and long cycle times, OTD may not be the first priority for improvement.

Key Success Factors for Managing OTD

Establishing the right capacity and maintaining a manageable backlog is critical. This requires implementing structured business processes to manage these areas effectively.

Steps to Improve On-Time Delivery:

Set Aggressive but Achievable Cycle Time Goals

1) Ensure key tests are completed before the sample due date.

2) These goals should be clearly defined for lab teams.

Track and Analyze Delays

1) Record reasons for delayed samples and test executions for continuous learning and improvement.

2) Monitor these reasons daily, weekly, and monthly using the Smart-QC Dashboard Summary.

3) In All-In-One, use Scheduling Reports to track trends and performance.

Ensure Capacity Supports Business Goals

1) Long-Term: Do we have enough resources to meet demand over the next few months?

2) Short-Term: Do we have enough resources to meet demand over the next few weeks?

3) Training Dashboard: Are team members trained in the correct methods/techniques for the upcoming weeks/months?

Optimize Equipment Utilization

1) Avoid over-utilization or reliance on a single point of failure, as these factors can negatively impact OTD.

Monitor Backlog & Balance Workloads in Smart-QC

1) Identify workload imbalances between teams.

2) Adjust resource allocation to improve overall efficiency.

Define Key Performance Indicators (KPIs)

1) OTD Lab (Samples)

2) OTD MFG

3) Due Date Fluctuation %

4) Test/Review On-Time %

5) Backlog and more

Use Smart-QC for Proactive Monitoring

1) Track Plan vs. Actual in Smart-QC Daily Interactive to maintain consistent OTD performance.

2) Utilize the Smart-QC Alert Module to display urgent tasks and at-risk activities, helping teams focus on critical priorities.

Sustained improvement in these key areas requires top management engagement and periodic KPI reviews.

By following these strategies, labs can achieve consistent and reliable On-Time Delivery performance with Smart-QC.