Approach to Managing a Lean Lab in Smart-QC

As more laboratories embark on lean lab initiatives, a common question arises: How do lean principles translate into a digital planning and scheduling solution like Smart-QC?

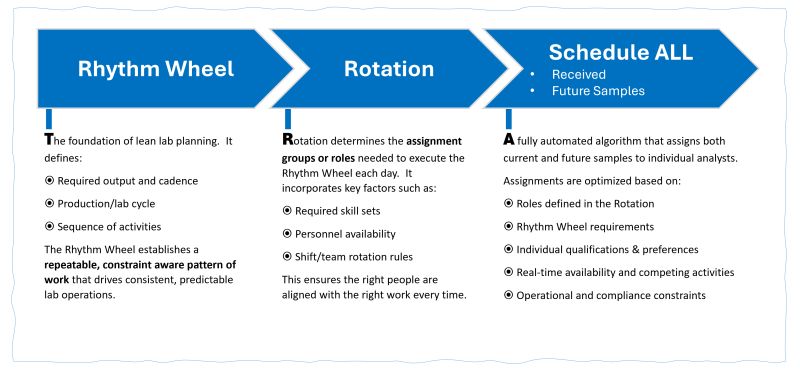

The answer: we’ve built a direct, structured conversion from lean lab methodology into Smart-QC’s digital scheduling engine—powered by three core processes.

1. Rhythm Wheel

The foundation of lean lab planning.

It defines:

✅ Required output and cadence

✅ Production/lab cycle

✅ Sequence of activities

The Rhythm Wheel establishes a repeatable, constraint aware pattern of work that drives consistent, predictable lab operations.

2. Rotation

Rotation determines the assignment groups or roles needed to execute the Rhythm Wheel each day.

It incorporates key factors such as:

✅ Required skill sets

✅ Personnel availability

✅ Shift/team rotation rules

This ensures the right people are aligned with the right work every time.

3. Schedule All

A fully automated algorithm that assigns both current and future samples to individual analysts. Assignments are optimized based on:

✅ Roles defined in the Rotation

✅ Rhythm Wheel requirements

✅ Individual qualifications & preferences

✅ Real-time availability and competing activities

✅ Operational and compliance constraints

Once your master data is set, Smart-QC delivers a fully automated, lean-optimized schedule bringing the principles designed by lean lab experts directly into day-to-day operations.