The Hidden Conflict Between Cycle Time and Efficiency in Lab Operations and How Smart-QC Resolves It

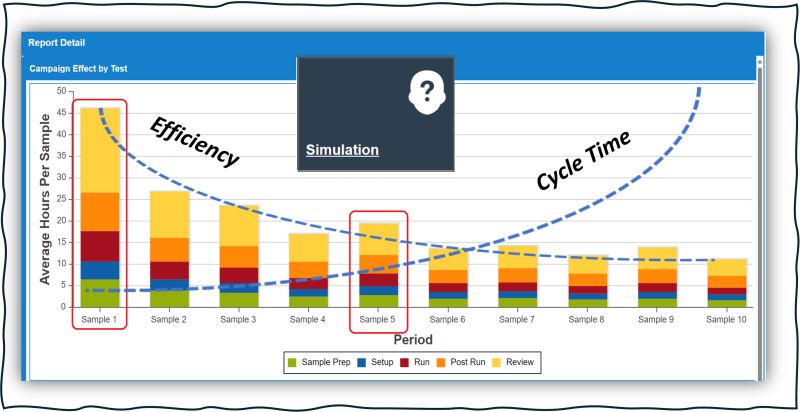

Anyone who has worked in a lab understands this reality: the more you campaign (batch) samples, the more efficient the process becomes.

Why? Because every run whether it includes 1 sample or several, requires the same fixed activities: Preparation, Equipment setup, Instrument warm-up, Result analysis and reporting and more … Adding more samples usually adds only incremental time, while the fixed “COST” remains the same.

Result: larger campaigns = higher efficiency

But here’s the problem: ⚡The Efficiency vs. Cycle Time Conflict⚡

To maximize efficiency, labs are incentivized to wait and accumulate samples until they reach an optimal campaign size (equipment limits, preparation time, shift constraints, etc.). However, this waiting time increases overall cycle time, which negatively impacts service levels.

This creates a fundamental conflict:

➡️ Wait longer to boost efficiency, or

➡️ Run sooner to reduce cycle time

Finding balance is the real challenge.

⚡How to Find the Sweet Spot⚡

Instead of “run each sample as it arrives” (a traditional Lean concept), labs must consider a minimum campaign size that respects both efficiency and turnaround expectations. Smart-QC helps resolve this conflict by using logic and simulation, but the principles apply universally.

Here are key levers labs can use:

- Forecast what’s coming (Predicting what’s coming); Even limited visibility into expected workload helps determine whether to wait or run now.

- Use simulation models: Simulations allow teams to test how different campaign sizes affect cycle time and efficiency.

- Apply business rules such as:

- – Minimum campaign size

- – Maximum allowed waiting time

- – Specific days or shifts allowed for batching

- Optimize the Efficiency/CT tradeoff (Smart-QC identifies the point where waiting longer no longer pays off) Identify the point, where waiting longer no longer improves efficiency enough to justify the cycle-time impact.

- Align with customers through CSAs: A well-defined Customer Service Agreement sets expectations and creates shared understanding of the batching logic.

Summary

In laboratory environments, the classical Lean concept of single-piece flow is often impractical and counterproductive. Instead, labs should define minimum viable campaign levels and use data-driven rules to balance efficiency and cycle time.

Finding this balance isn’t just a scheduling decision, it’s a strategic one. Smart-QC makes this balance data-driven, predictable, and repeatable