Value Add in QC Lab Operations; Overall Lab Effectiveness (OLE)

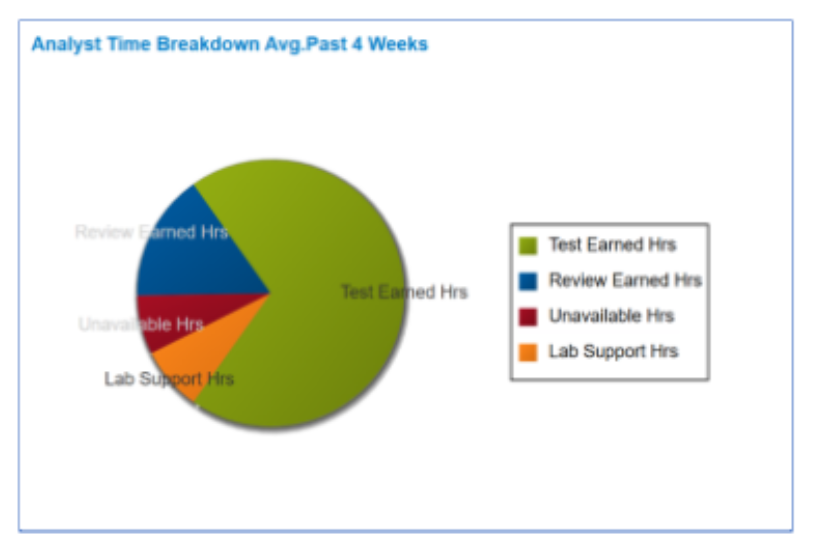

One of the biggest challenges in QC labs is defining and measuring efficiency. Many describe value-add as only the activities that drive lot release; mainly testing and review. In reality, analysts spend significant time on other essential tasks:

- cleaning,

- calibration,

- training,

- investigations, and of course vacations and absences.

Unlike semiconductor manufacturing, where OEE (Overall Equipment Effectives) is used because equipment is the core asset, in QC the real asset is the analyst. This is why applying classic OEE doesn’t work directly.

A practical approach is to focus on the hours truly available for testing after deducting all non-test activities. These “remaining hours” can then be compared to the actual test and review standard hours completed. This becomes a simple but powerful indicator of lab efficiency.

Example: If a lab analyst has 20 hours remaining for testing and completes four HPLC campaigns that each take ~5 hours, then 20 hours of value-add were achieved out of 20 hours available—100% efficiency.

From this idea, you can define an Overall Lab Effectiveness (OLE) similar to OEE: OLE = value-add hours (test + review) ÷ total analyst hours.

But the key message is this: Efficiency alone can be misleading. A lab may show 100% efficiency but still deliver low output if too few hours were available for testing. To stay healthy, labs must ensure that value-add testing time represents at least 15–20 hours of the total hours each week (or similar benchmark).This keeps the lab focused not just on efficiency—but on maintaining real, sustainable testing output.