Ideal Supervisor-to-Analyst Ratio in QC Laboratories

The supervisor-to-analyst ratio in Quality Control (QC) labs can vary depending on factors such as lab size, complexity, and regulatory requirements.

Based on industry benchmarks, here are some typical ratios:

- Typical Ratio: In many QC labs, a common ratio is 1 supervisor for every 6 to 10 analysts. This ensures supervisors can oversee workloads, maintain quality standards, and provide necessary guidance and troubleshooting.

- Smaller Teams: In smaller labs, the ratio might be 1 supervisor for every 4 to 5 analysts, allowing for more hands-on supervision in a concentrated environment.

- Larger Teams: In larger QC labs, the ratio can shift to 1 supervisor for 10 or more analysts, with senior analysts or team leads helping to distribute supervisory duties.

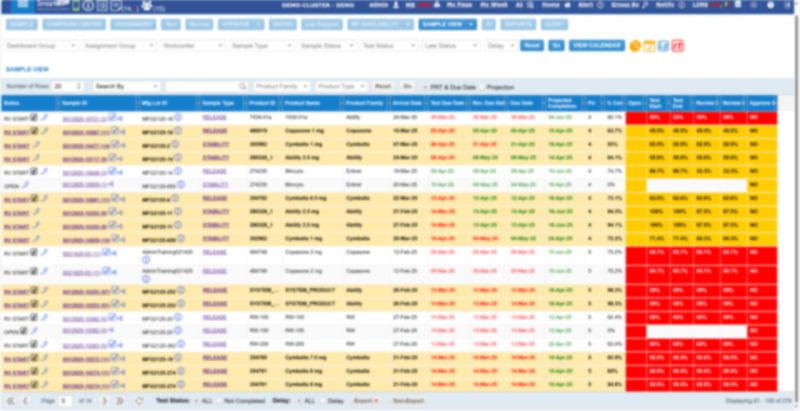

While these ratios are general guidelines, the ideal ratio depends on the lab’s specific needs—✅ volume, ✅ complexity, and ✅ analyst experience. Moreover, the introduction of Smart-QC can help optimize this ratio by streamlining tasks such as 👉scheduling, 👉 communication, 👉 reporting, and 👉 KPI tracking, ultimately reducing the supervisor’s workload and enhancing overall efficiency.

By minimizing the day-to-day burden of managing schedules, assignments, and reprioritizations, supervisors can take on more direct reports, effectively expanding the supervisor-to-analyst ratio. In fact, with Smart-QC’s features—such as analyst scorecards, service level monitoring, and more — other supervisors can easily step in as backups when needed.

📊 What’s your lab’s current ratio? And how are you optimizing it?